How to print on Egg Cartons

Egg Batch and Date Codes Required: What Ink for Polystyrene, Plastic or Cartons?

Egg farms around the globe are switching to Inkjet technology for the coding of variable information on their egg cartons. Manufacturers are required to mark information on their packaging such as lot/batch numbers, expiration dates, and barcodes.

The information on egg cartons (carton, polystyrene or plastic) is important for tracking individual units as well as batches of units, quality control, and aiding in the sale of the products. Coding this information onto egg cartons is a necessary and vital part of the product’s life cycle.

Printing on paper pulp Egg Cartons instead?

We also offer ink solutions for porous egg carton materials (ie pulp cartons), as those volumes continue to hold steady at egg packaging facilities.

Low Cost TIJ Date Code Solution

Case Printing Solutions offers coding solutions designed to perform across a wide range of packaging styles and materials such as pulp, plastic,and foam. The full product line –based on HP THERMAL INKJET TECHNOLOGY -includes both industrial inks and printers. Collectively these solutions give the farms and egg packers the ability to adapt to future line changes.

Egg Carton Coding Requirements:

Egg packaging is classified into paper (paperboard, recycled paper, and molded cup) and plastic (polyethylene terephthalate and polystyrene), and further broken down by cartons and trays.

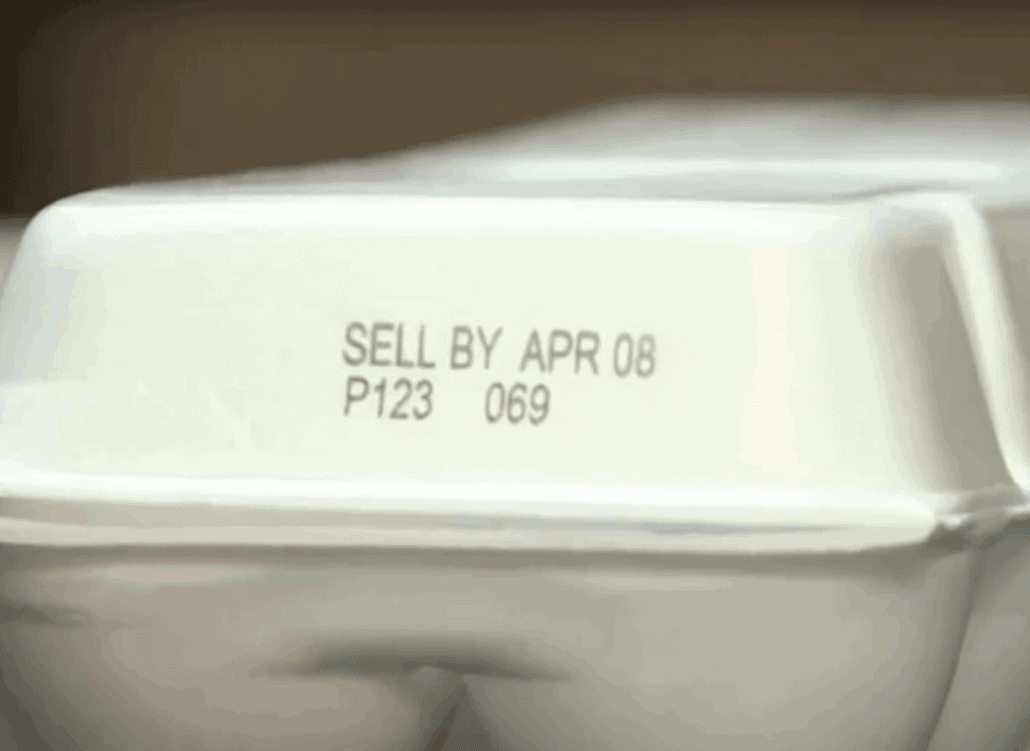

Carton coding is a requirement for egg farms and factories across the U.S. High resolution digital printing on egg cartons ensures retailers can manage inventory, Consumers can check freshness of the product, and regulatory requirements are met for identifying and tracking products. If eggs are packed under USDA’s grading service, the cartons can bear theUSDA grademark. According to the USDA, when the USDA grade shield is present on the carton, the carton must also be labeled with the date and location of where the eggs were packed.The pack date (the day that the eggs were washed, graded and placed in the carton) is a three-digit code that represents the consecutive day of the year (the “Julian Date”) starting with January 1 as 001 and ending with December 31 as 365. When a “sell-by” date appears on a carton bearing the USDA grade shield, the code date may not exceed 45 days from the date of pack. Most state requirements are similar.