https://caseprintingsolutions.com/wp-content/uploads/2022/03/hemp-science-1280x720-web.jpg

720

1281

Jeremy

https://caseprintingsolutions.com/wp-content/uploads/2020/06/CPSLogoold.gif

Jeremy2022-03-22 16:55:132023-10-27 13:01:32Hemp Compounds Effective against COVID-19 Per OSU Research

https://caseprintingsolutions.com/wp-content/uploads/2022/03/hemp-science-1280x720-web.jpg

720

1281

Jeremy

https://caseprintingsolutions.com/wp-content/uploads/2020/06/CPSLogoold.gif

Jeremy2022-03-22 16:55:132023-10-27 13:01:32Hemp Compounds Effective against COVID-19 Per OSU ResearchPharma Coding Success

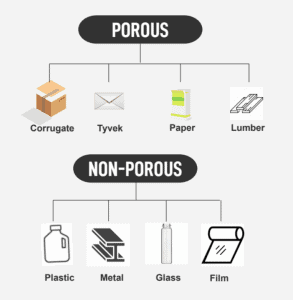

Content, Batch and Date Codes Required: What Ink for Foils, Plastic Pouches or Drams?

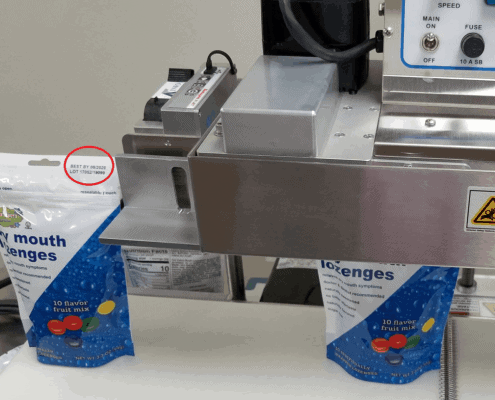

Pharma packaging and testing firms are switching to Inkjet technology for the coding of variable information on kits, materials and reagents, as well as retail products and institutional products. Pharma manufacturers and packagers are required to mark information on their packaging such as lot/batch numbers, expiration dates, and barcodes.

The variable data is important for regulatory compliance, as well as tracking individual units as well as batches of units, quality control, and aiding in the sale of the products. Coding this information directly onto packaging saves labeling costs, and reduces errors.

Low Cost Thermal InkJet Systems for Efficiency, Savings

Low cost thermal inkjet systems, such as the Markoprink X1Jet, can reduce costs from labeling, and bring huge savings and efficiency for small batch and variable data requirements. Contact Case Printing Solutions to get a total cost of ownership savings estimate and find the right printer and ink for your application.

Save vs Labeling

Labels = Labor Costs

Save costs with off line printing vs labeling

Save on product labeling. Your biggest cost is labor. As you scale up production, the inefficiencies of manual labeling will hurt throughput. With in-line digital direct coding, you can minimize your up-front capital costs and still save every month on labor and supplies

Low Cost TIJ Date Code Solution

Case Printing Solutions offers coding solutions designed to perform across a wide range of packaging styles and materials such as pulp, plastic,and foam. The full product line –based on HP THERMAL INKJET TECHNOLOGY -includes both industrial inks and printers. Collectively these solutions give the farms and egg packers the ability to adapt to future line changes.