How to print codes on Wood

Coding & marking of lumber: furniture, flooring and other wood products

- Challenges – dusty, dirty, temperature extremes, irregular printing surfaces, run virtually nonstop

- What’s Needed – Uptime Uptime Uptime. Reliable and robust equipment, minimal maintenance, quick ink changes, durable codes

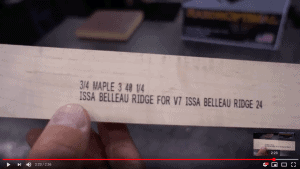

- Variable Codes – dimensions & specifications, dates, bar codes, moisture levels, panel grades, inspector ID, species, lot or batch numbers, and traceability data

- Wood Products – from raw lumber to coated or varnished wood for furnishings, flooring, and other finished items

Parts Labeling for Assembly

A typical cabinet job has 100 or more parts. Coding technologies like RAZORGAGE enables “clean parts and the ability to print the parts in random order,” said Rod Edel, owner and CEO of EdelCabinetsDirect. Parts are cut in random order to optimize material use, so marking is essential for final assembly. The system performs the labeling by printing directly onto the wooden parts. In process codes include two lines of print for: room number, cabinet number, dimensions of part, and job name.

Case Printing Solution Inks + Training = Improved Uptime and Print Quality

The RAZORGAGE figures out the best way to optimize the raw parts before any cuts are made. But when the printer stopped working, the line was down. Case came in and trained us in appropriate printhead cleaning procedures, which totally fixed the issue. Getting Edel Cabinets up and running.

EDEL CABINETS DIRECT

RTA CUSTOM CABINETS

Albany, Oregon

System: RazorGuage RazorOptimal Cyclone

Ink Choice:

Case Printing Solutions Remanufactured Evolution 4500 Pigment ink cartridges

“After struggling for months with the Chinese-built solution from AliBaba, we called Case and they designed a new solution that had us up and running in weeks. They were able to reduce our labor cost for hand labeling. We went from 8 people working 8 hours a day to 2 people working 2 hours a day, a 75% labor savings!“

~ Rod Edel,

CEO EdelCabinetsDirect

Printing on Laminate or “sealed” surfaces instead? Try Solvent Inks

We also offer ink solutions for laminate and non-porous materials.

Did you know that you can use pigment ink on Laminates, and then easily wipe off after assembly?

Other advantages of Case Fast Dry Solvent ink with Long Decap include:

- Ability to print on glossy labels found on some egg cartons

- Longer shelf life, so the ink doesn’t dry-out in the print nozzles

- Improved smudge resistance, compared to other solvent black inks

The Fast Dry LD solvent black ink can be printed from virtually all cartridge inkjet coders (based on the HP inkjet technology) found on our list of approximately 30 printer companies. To test the print quality of Fast Dry LD Solvent Ink on your specific substrate, we will gladly produce print samples for you on your substrate.

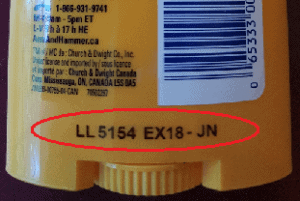

Low Cost TIJ Date Code Solution

Case Printing Solutions offers coding solutions designed to perform across a wide range of packaging styles and materials such as pulp, plastic,and foam. The full product line –based on HP THERMAL INKJET TECHNOLOGY -includes both industrial inks and printers. Collectively these solutions give the farms and egg packers the ability to adapt to future line changes.