Packaging Automation that Helps Labor Constraints

Streamline your Production Line

Manufacturers in virtually every industry are leveraging automation to streamline tasks, increase efficiency, and minimize costs. This is especially the situation in packaging where companies reap big financial rewards for improving the capacity of high-volume manufacturing lines.

Variable Data Printing Automation – Replace labels with Direct Printing

Variable Data Printing Automation – Replace labels with Direct Printing

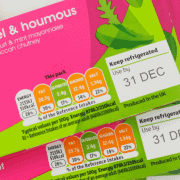

Case Printing Solutions (CASE) – a U.S. based company with deep roots in printing technology – makes it their primary goal to help other companies reduce packaging costs. The specific area of expertise at CASE is to streamline the coding of variable data on products and packaging. Such variable data includes alphanumeric codes like lot/batch and expiration dates, linear and two-dimensional barcodes, and small graphics. This data cannot be pre-printed by the manufacturer because actual packaging dates and production details are unknown at the time of pre-printing.

Higher Volumes require Smarter Solutions

Over the past few years, CASE has discovered a valuable opportunity for its products and services in food, pharmaceutical, and cannabis applications. More and more of these manufacturers have a need to label or code flat packaging materials at increasing production speeds. What began for many of these companies as a small hand-labor task, has now exploded into a high-volume operation where labor is the bottleneck. This is precisely the opportunity where CASE can assist.

RF LITE

“This machine has been fantastic. It has slipped into our operation and become an invaluable part of our process. It is hard to imagine how we ever managed without it. Coding used to be slow, painful and labor intensive. Now a single operator can run off 5000 sleeves in just two or three hours.”

-Food manufacturer

Integrated Feeder and InkJet Coders

The buzz phrase used at CASE is Integrated Feeder Solutions. This is the merging of high-speed, high-volume feeders with industrial inkjet coders in order to print variable data on packaging materials. Substrates that are typically run through the integrated systems include sleeves, flat cartons, hang cards, plastic cards, and zipper bags. Friction feeders are the first alternative due to lower capital cost. However, for many of the bags and pouches, a vacuum feeder with pick & place technology is an option.

Get an estimate for your packaging line

Companies looking to trade-off labor for affordable automation systems are encouraged to contact CASE at (541) 754-2273. We’re available to run your substrates on our feeder/coding systems to determine factory acceptance.