7 Reasons Inkjet is the Best Fit for Case Coding

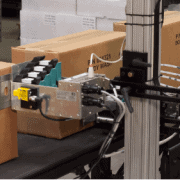

In the past decade HP inkjet has become the coding tool of choice for a multitude of carton and case coding applications in the packaging industry. From product identification, to carton marking, to corrugate case coding and more, the benefits of HP inkjet are many. Legacy technologies like label print & apply are no longer the preferred printing method.

Here are 7 reasons to strongly consider HP inkjet when exploring coding technologies. How does your current case coding system stack up?

1. Durable Print Systems

HP inkjet systems come in all shapes and sizes. Select a case coder built with stainless steel housing so it’s as industrial as the rest of your packaging operation. A select few of the HP inkjet systems are available in wash-down models for dusty environments.

2. Ink / Substrate Compatibility

HP inkjet case coders are designed with the specialty inks in mind to yield maximum compatibility and optimum performance. CASE Printing Solutions extends the range of possible inks that can work with the customer’s substrates. We can offer comparable case coding ink products at a significant discount. Additionally, HP inkjet supplies don’t reply on noxious inks that are harmful for the operators, as you would find with legacy print technologies.

3. Low Maintenance / No Expensive Contracts

Most procurement managers would not intentionally buy a case coding system with high maintenance requirements. Nonetheless, there are legacy print systems in the market today that require regular shutdown, cleaning and parts replacement. With HP inkjet case coders there’s a need for continuous duty cycles. The act of cleaning a print head is as simple as wiping with a lint-free cloth.

4. Few Repair Parts

HP inkjet case coders have virtually no wear parts. For the cost of a new ink cartridge, the customer also gets a new print head. Try that with piezo or continuous inkjet! In rare situations where the HP inkjet printhead gets damaged, quality suppliers like CASE Printing Solutions have all the parts and know-how to save the customer from having to buy a new coding system.

5. Go Bulk and Save

Commit to implement a significant, cost saving bulk ink strategy for your packaging line. If you’re currently using disposable print cartridges as your ink delivery system, consider a Bulk ink system. Case Printing Solutions regularly helps customers reduce cost-per-print by 50% when a Bulk system is capable of handling the job.

6. High Print Quality

HP inkjet originated in home printing, so you get tremendous flexibility in terms of print resolution. For high res coding applications you can print 250 mpm at 600 x 300 dpi. This is recommended when printing barcodes so there’s no issue reading codes and passing retailer requirements. Or you can reduce the print resolution to 600 x 150 to cut your ink costs in half. The print quality of inkjet coding at 150 dpi is still better than most other print technologies.

7. Ease of Training Operators

When deploying HP inkjet case coding you also simplify the training and operations on the packaging line. CASE Printing Solutions works with its customers to document the most efficient use of their case coding systems. As a result, when an employee transitions out of the packaging department the upheaval is minimized and the operation is not compromised.