Coding Egg Cartons with Thermal Ink Jet

Carton coding is a requirement for egg farms and factories across the U.S.

High-resolution digital printing on egg cartons ensures Retailers can manage inventory, Consumers can check the freshness of the product, and regulatory requirements are met for identifying and tracking products.

The global egg packaging market in 2018 was $5.25 billion and is expected to reach approximately $8.15 billion by 2025 (CAGR of 6.5%). One of the driving factors of the sustained growth is that Consumers are preferring eggs over meat as a safe and inexpensive source of protein. One uniqueness of the egg packaging market is the delicate nature of eggs, as they require careful packaging in order to prevent loss or damage. Conventionally used cartons and trays are meant to sustain shocks during transportation and handling. Additionally, their outer surfaces form an additional fitting that safeguards eggs from dislocation and prevents physical damage.

Egg Carton Coding Requirements:

Egg packaging is classified into paper (paperboard, recycled paper, and molded cup) and plastic (polyethylene terephthalate and polystyrene), and further broken down by cartons and trays.

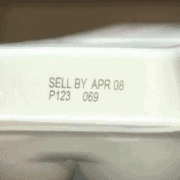

Carton coding is a requirement for egg farms and factories across the U.S. High-resolution digital printing on egg cartons ensures retailers can manage inventory, Consumers can check the freshness of the product, and regulatory requirements are met for identifying and tracking products. If eggs are packed under USDA’s grading service, the cartons can bear the USDA grademark. According to the USDA, when the USDA grade shield is present on the carton, the carton must also be labeled with the date and location of where the eggs were packed. The pack date (the day that the eggs were washed, graded, and placed in the carton) is a three-digit code that represents the consecutive day of the year (the “Julian Date”) starting with January 1 as 001 and ending with December 31 as 365. When a “sell-by” date appears on a carton bearing the USDA grade shield, the code date may not exceed 45 days from the date of pack. Most state requirements are similar.

Low-Cost TIJ Date Code Solution

Case Printing Solutions offers coding solutions designed to perform across a wide range of packaging styles and materials such as pulp, plastic, and foam. The full product line –based on HP THERMAL INKJET TECHNOLOGY -includes both industrial inks and printers. Collectively these solutions give the farms and egg packers the ability to adapt to future line changes. Some of the critical features and benefits of the print technology include:

- Print Quality: high-quality, consistent codes on all surfaces which are configurable up to 600 dpi

- Ease of Use: snap in and out cartridges to change supplies; make messages quickly using WYSIWYG software

- Uptime: low to no maintenance of inks and printers; stands up to challenging environments including dust and temperature extremes

- Throw Distance: allows non-contact printing on egg cartons up to 5mm away

- Compact: small footprint enables tight integrations on most egg packer machinery